Sanitizing Tunnel / Sanitization tunnel / Sanitizing Booth is designed to disinfecting personnel by passing through disinfectant passageways, which sprays disinfectant and sanitizer to kill 99.999% of viruses, bacteria, fungi, molds & spores.

The Sanitizing Tunnel / Sanitization tunnel / Sanitizing Boot is a non contact contamination automatically control device. It restricts spreading hazardous viruses for entering human bodies & effecting respiratory system. When the occupant moves, the viruses gets active to find human body for living resting on his/her body & clothing for entering the human body for being spread in respiratory system by reproductive methods. The Sanitizing booth is to assassinate the suspension of the contamination viruses/particulate by exploiting them on body itself before entering the human breathing zone. By virtue of what the Sanitizing booth is doing, it also reduces contamination for being spread into different communities & area by means of personal movement. The sanitizing booth works by gently transmitting a disinfectant such as IP liquid etc. over surface of an operator’s body & clothes, causing the kill of the viruses stacked to the person body & clothes instead of becoming airborne & spreading to others.

Sanitizing Tunnel Uses:-

Sanitizing Booth is a tailor made product which cans differ in shapes & dimensions depending on site measurement & space constrains. This can be widely used at entry/exit of public places as follows:-

- Hospitals entry & exits, especially at ICU Entry & exit doors doe medical staff safety

- Communities main doors

- Airports & railway stations

- Factories, supermarkets, shopping malls, construction sites

- Institute & Schools Main doors

- Banks & hotels

Sanitizing Tunnel Working Principle:-

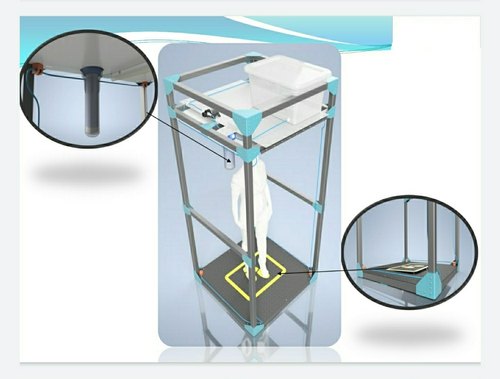

- A self-preventive modular chamber with human sensors designed to deliver disinfectant on every individual passing through it

- The Sanitizer Tunnel works through a central disinfectant mist generation and distribution arrangement located above the internal chamber & on the side walls which ensures that the operator is fully sterilized before entering any premises

- The system is supplied with sanitizing nozzles to drop suitable size curative particulates which are placed such that mist spray will be possible on and all around the person passing through it

- The system will operate for a duration as per the person entry & exit inside the unit. During the operation the operator is expected to gently rotate in the central space with his/her elbows raised and away from his body to get best results of system

- During this misting cycle, the operator twists his/her body and moves his/her arms up and down to reduce any folds in the clothes and to help ensure uniform coverage. After a person exit the system, the sanitizing cycle automatically shuts off.

- These are both-way rooms. In Sanitizing shower, highly pressurized disinfectant is spread on suit of person to drain the contamination. This prevents passing out of hazardous viruses from being circulating in different areas while person movement process.

- Sanitizer Tunnel provides gentle wetting of all exposed surfaces of the operator’s garment, digesting hazardous particulate.

- Disinfectant Consumption is 0.5 liter per minute misting cycle.

Standard Features

- SS Spray Nozzle for fine mist disinfectant spraying during operation having semi hollow cone spray pattern with droplets size 40-70 microns with spray angle of 60° dense pattern/90° non dense pattern at around 5-7 bar pressure

- Single wall Construction with covering piping

- Automatic on/off operated with personal movement sensors

- Self -Priming Monoset Pump for providing jet flow of disinfectant to take care of flow requirement

- Open able & Lid covered tank with 30 ltrs. capacity for disinfectant storage

- Disinfectant type to be used are 100-400ppm diluted solution of chlorine dioxide or 200ppm diluted solution of hypochlorous acid

- Solenoid valve for disinfectant liquid controlling during cycle

- Acrylic sheet covering on sides & top for better luminance inside the unit

- Drain in water tank for tank cleaning

- Low & High Level Indication for disinfectant Storage inside tank

Options and Accessories available at an extra cost

- Temperature measurement of infrared ray & audio/visual alarm with following functions:-

- Key data such as Register attendance & travel record

- Statistical analysis chart of body temperature & personnel

- Face recognition & Id check

- LED light for providing 400 LUX

Power Supply: 220 VAC 1-Ø 50 Hz – 60 Hz Documentation

- Design Qualification

- Installation Qualification

- Operational Qualification

- As Built Drawing & Electrical Wiring Drawing

- Operational & maintenance manual

Site Requirements

- The unit will be provided with 5 mtr. Long cable. Any cabling required between unit to the electrical control panel will be in Client’s scope

- Concealing of electrical cabling (if any required) is in Client’s scope.

- Client to provide the location of the control panel on the service panel near water tank

- Utility Connection and Electrical power supply will be in client’s scope

- Cleaning Utility, Waste material disposable will be in client’s scope

- A) Sanitizing Tunnel with PPGI panels of 50mm thickness for the top and both side

- B) Sanitizing Tunnel with powder coated MS pipes, flexible PVC sheet for covering the top and both side walls.

Note: Stansard size: 3000mm (L) x 1200mm (W) x 2400mm (H) Each unit will be provided with a 30 litres PVC tank, connecting hoses and cables, misting nozzles, auto sensor for man entry/ exit and a 1/2 HP pump.

For More Details Call @ 9780681004

Suppliers of Sanitization tunnel / Sanitizing Booth In India , Suppliers of Sanitization tunnel / Sanitizing Booth In Himachal , Suppliers of Sanitization tunnel / Sanitizing Booth In Punjab , Suppliers of Sanitization tunnel / Sanitizing Booth In Haryana